Spend $25 to be eligible for FREE SHIPPING!

Minimum order activates Free Shippingoption on check out page.

Vapco Products

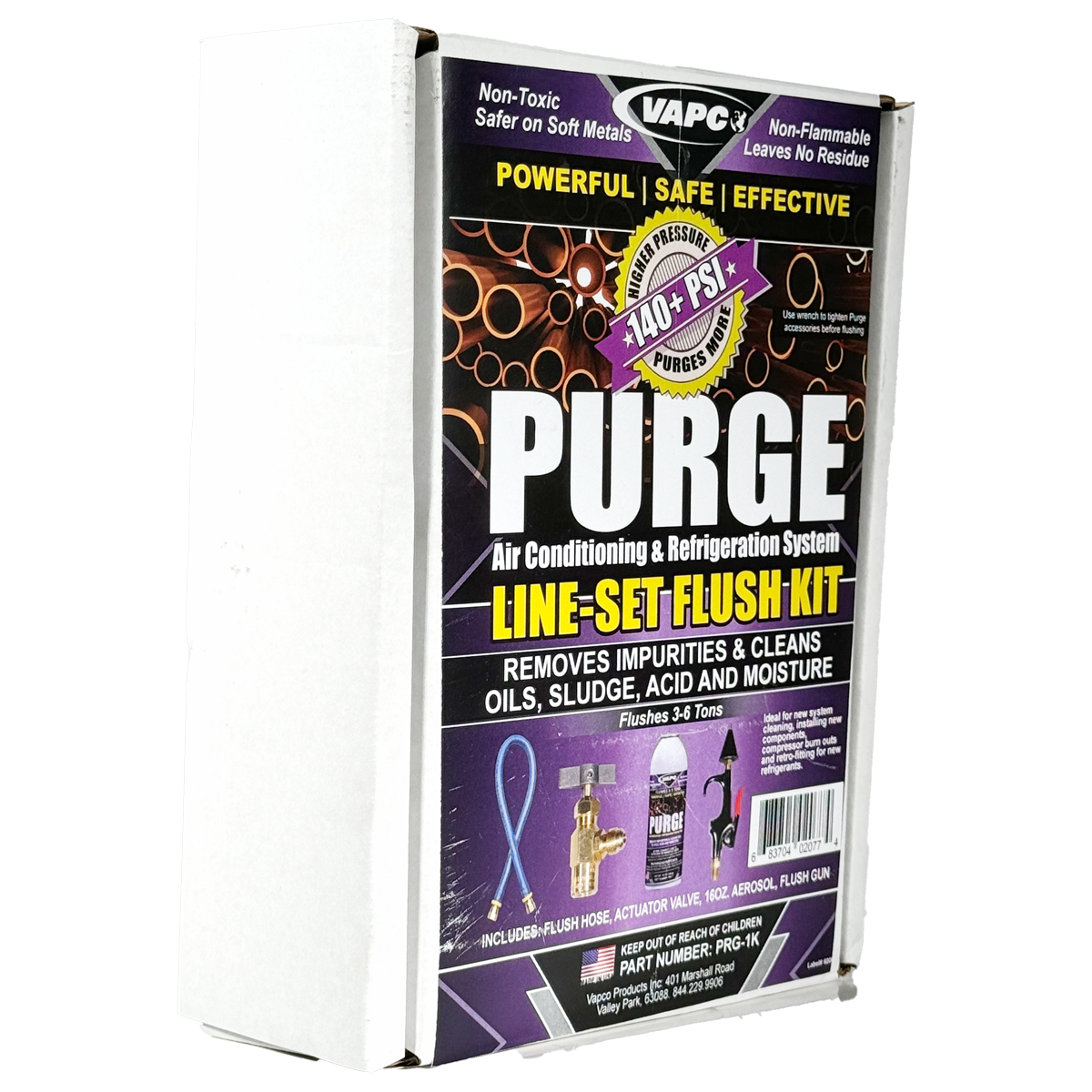

Purge Line Set Flush – Starter Kit

Purge Line Set Flush – Starter Kit

Couldn't load pickup availability

Conquer Contamination: The PURGE Line Set Flush Starter Kit

Get everything you need for a sparkling clean HVACR system in one shot! The PURGE Line Set Flush Starter Kit is your all-in-one solution for removing harmful contaminants that can clog your lines and reduce efficiency.

This kit includes:

- 1 lb Can of Purge System Flush: The industry's most powerful line set flush, blasting away debris with over 140+ PSI for heavy-duty cleaning.

- Flush Gun: Effortlessly apply the cleaning power of Purge for a thorough clean.

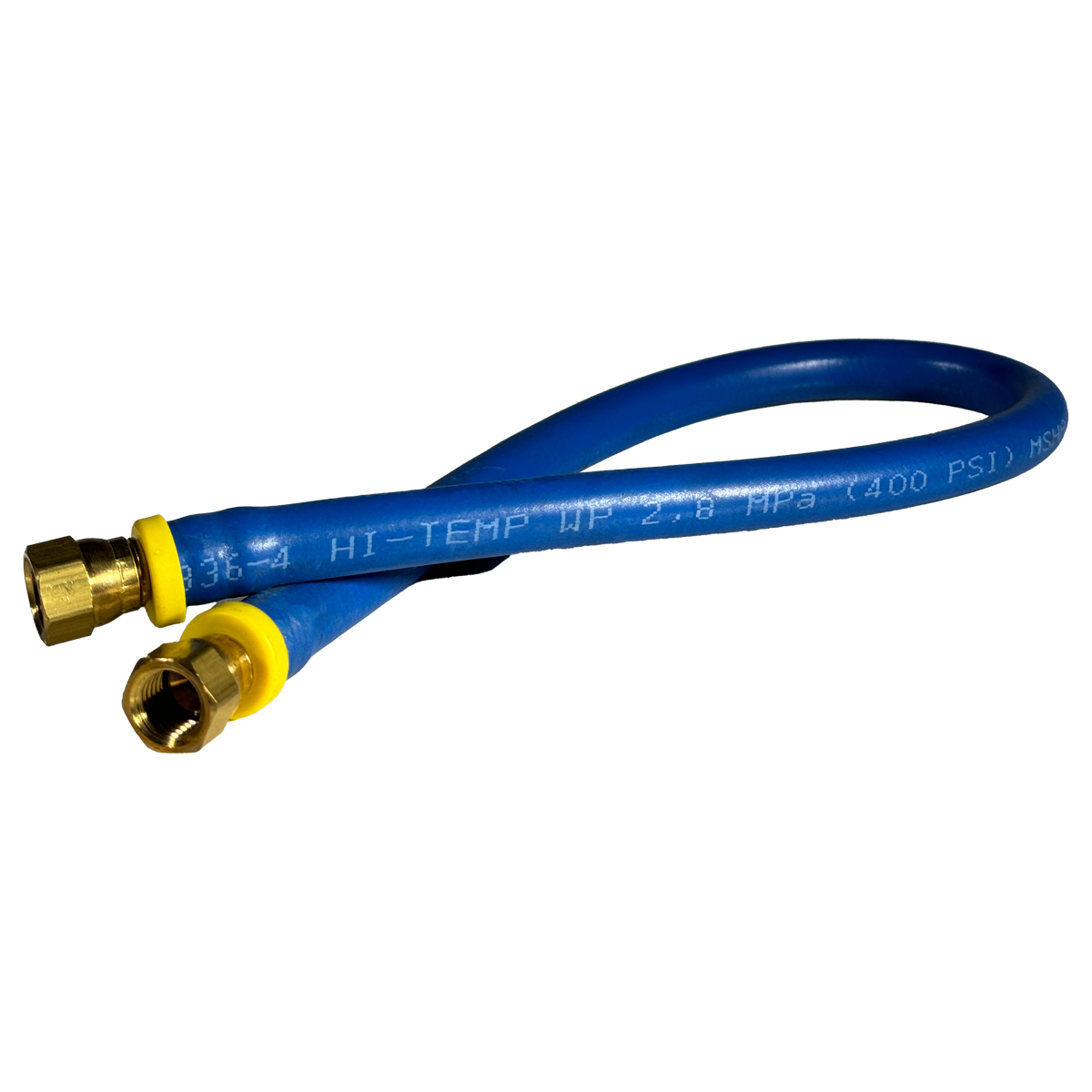

- Hose: Ensures easy reach and maneuverability during the cleaning process.

- Actuator Valve: Provides controlled application of the flush for optimal cleaning.

Purge tackles a variety of HVACR cleaning needs:

- Post-Burnout Revival: Restore your system after a burnout by eliminating leftover debris and residue.

- Conversion Confidence: Prepare for a smooth refrigerant conversion by removing contaminants that could cause problems.

- New System Startup: Start fresh with a clean system! Purge eliminates contaminants in new components for peak performance from the beginning.

Clean Doesn't Mean Harsh: Purge is a powerful yet safe solvent that removes:

- Sludge

- Carbon Residues

- Oil

- Acids

- Moisture

- Particulates

from your condensers, evaporators, and line sets. All without long-term environmental or health risks!

Why Choose the PURGE Line Set Flush Starter Kit?

- Complete Solution: Everything you need for professional-grade cleaning is right here.

- Powerful Cleaning: Experience the industry's strongest line set flush for unmatched cleaning power.

- Safe & Effective: Clean with confidence, knowing Purge is formulated for safety.

- Versatile Application: Use Purge for various cleaning needs across your HVACR system.

Invest in a clean and efficient HVACR system! Add the PURGE Line Set Flush Starter Kit to your cart today and experience the difference a powerful clean can make. Breathe easy, knowing your system is running smoothly!

This is a professional grade HVAC product. It is crucial that you adhere to all directions and precautionary statements to prevent injuries.

Directions

Directions

DIRECTIONS:

- WEAR SAFETY GLASSES AND GLOVES

DURING USE. - NEVER CONNECT CAN TO NITROGEN OR MANIFOLD SETS.

FAILURE TO INSURE SYSTEM IS DEPRESSURIZED (FREE OF PRESSURE) MAY CAUSE CAN TO BURST AND COULD RESULT IN INJURY.

- Use in well ventilated area.

- Review the configuration of the system.

- Consider cleaning the condenser, evaporator and

line-sets separately.

For larger systems, disassemble and clean in sections.

- Remove filter driers/cores, bypass thermostatic expansion valves, compressor, accumula-

tors, receivers, reversing valves, etc. - Never inject into compressor.

- If possible, crimp/restrict the line-set.

- This allows for added vigor during procedure. Use an open container to catch oil and debris from procedure.

- With valve turned out, install valve and gun/hose to canister.

- Open valve to dispense contents. Inspect collected solvent for cleanliness.

- Repeat if necessary.

- Purge system with 100-120 psi nitrogen to clear remaining solvent.

- Reconnect your system components.

Evacuate the systems, leak check, add oil and refrigerant.

Precautionary Statements

Precautionary Statements

Precautionary statements:

- Avoid breathing dust/ fume/gas/mist/vapors/spray.

- Wash hands thoroughly after handling.

- Use only outdoors or in a well-ventilated area.

- Wear eye protection/face protection.

- IF INHALED: Remove person to fresh air and keep comfortable for

breathing. - IF IN EYES: Rinse cautiously with water for

several minutes. Remove contact lenses if present and

easy to do. Continue rinsing. - Call a POISON CENTER/ doctor if you feel unwell. If eye irritation persists: Get medical advice/attention.

- Store in a well-ventilated place.

- Keep container tightly closed.

- Store locked up.

- Protect from sunlight.

Dispose of contents/container to specifications of local, regional , national, and international

regulations.

Share